PVD

PVD finishes are extremely solid and durable over time.

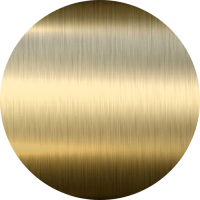

BB - Brushed Brass PVD®

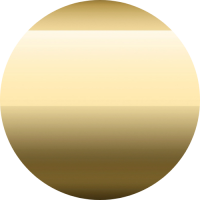

PB - Polished Brass PVD®

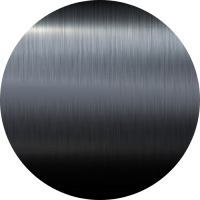

BOX - Brushed Onyx PVD®

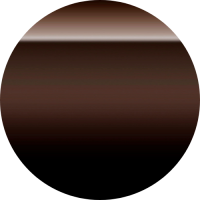

OX - Onyx PVD®

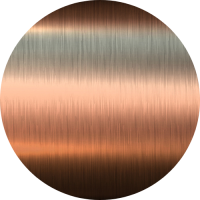

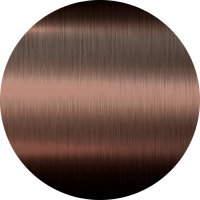

BRG - Rose Gold / Brushed Copper PVD®

RG - Rose Gold / Polished Copper PVD®

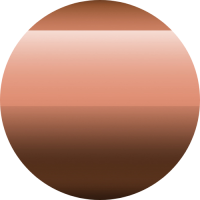

WB - Warm Bronze PVD®

PRB - Polished Tuscan Bronze PVD®

BRB - Brushed Tuscan Bronze PVD®

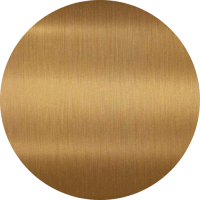

BG - Brushed Gold PVD®

BNP - Brushed Nickel PVD®

PNP - Polished Nickel PVD®

SG - Satin Gold PVD®

PG - Polished Gold PVD®

GM - Gunmetal PVD®